Cleaning the Cone

The cone requires regular preventative maintenance. Agilent recommends cleaning the cone on a weekly to monthly basis.

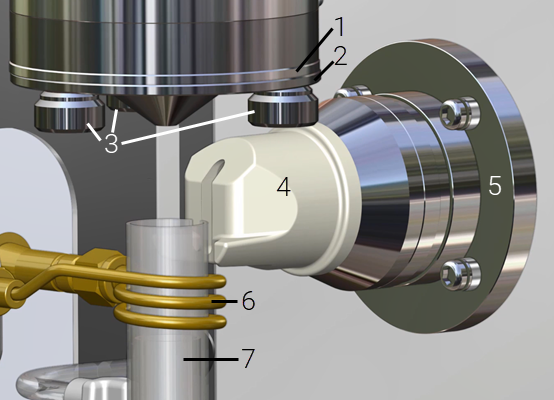

Torch compartment

Where:

|

1. Axial window assembly |

4. Snout |

7. Torch |

|

2. Cone |

5. Radial window assembly |

|

|

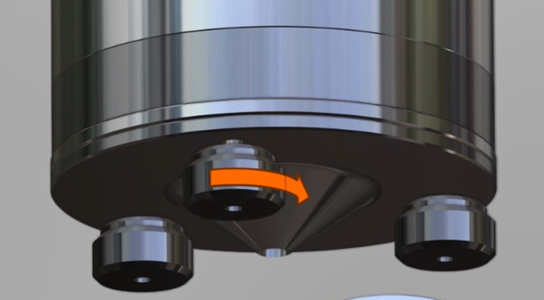

3. Cone thumb screws |

6. RF coil |

|

|

Chemical Hazard and Hot Surface Allow several minutes for the cone to cool down before removing it. |

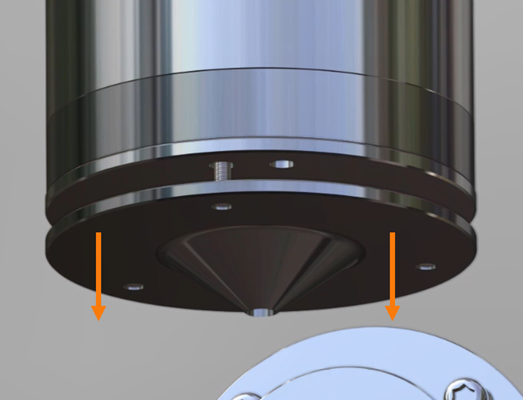

- Remove the torch (if present) and then snout by pulling it towards the front of the instrument.

- Undo the three thumb screws holding the cone in place. See image above.

- Pull the cone off of the axial window assembly.

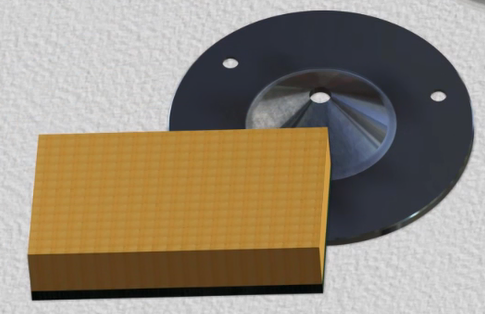

- Dip the cone in deionized water and scrub with a scourer. Alternatively, use a damp soft cloth and a suitable cleaning powder (such as a stainless steel cookware cleaner).

- Clean the orifice and both sides of the cone. Rub in a circular motion.

- Rinse the cone well in deionized water and then dry with a clean cloth.

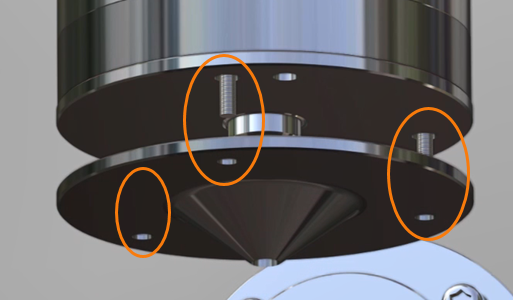

- Line up the screws with the holes in the cone and push the cone onto the axial window assembly.

- Tighten the thumb screws firmly by hand.

|

If the thumb screws holding the cone in place are not tightened firmly enough the cooling properties of the cone may be affected. |