Torch Overheating

If you observe yellow or orange coloration of any part of the torch, not due to the sample being presented or recently run, the torch is overheating. Switch off the plasma immediately.

|

If any unexpected red or yellow coloration appears in the plasma, or if the torch appears to be visibly melting, switch off the plasma immediately. Perform the torch cleaning procedure soon as any discoloration appears on the outer tube of the torch. To prevent damage to the instrument, do not use the torch if it is damaged. |

Check that the torch is undamaged and inserted correctly into the ICP-OES. For correct positioning of the torch refer to the calibrating the instrument.

Ensure that argon is flowing from the nebulizer into the spray chamber and the torch.

Check for kinks in the nebulizer gas tubing and replace if necessary.

Check for adequate gas flow from the argon source. Check the RF power and plasma gas flow settings. Using high RF power with low plasma gas flows will result in the torch overheating. Increase the plasma gas flow and/or reduce the RF power.

|

A plasma that sits too low in the torch, or is unevenly distributed within the torch, may damage the torch. If this is observed, replace the torch, inspect the sample introduction components and ensure the gas flow rate is correct. See below for more information. |

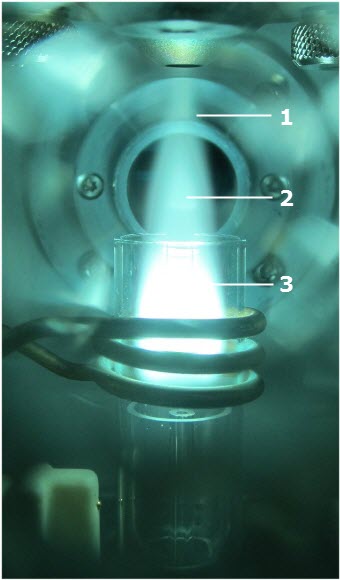

The plasma consists of several zones, as shown below:

ICP-OES plasma zones

- Plasma tail - appears red with yttrium solutions and yellow with sodium solutions. The plasma tail extends beyond the NAZ and is cooler than the NAZ. The plasma should be located centrally in the torch, and should look symmetrical.

- Normal analytical zone (NAZ) - where most elements emit most intensely. This region appears blue with yttrium solutions and almost colorless with sodium solutions.

- Induction zone - where energy from the induction coil is coupled into the plasma